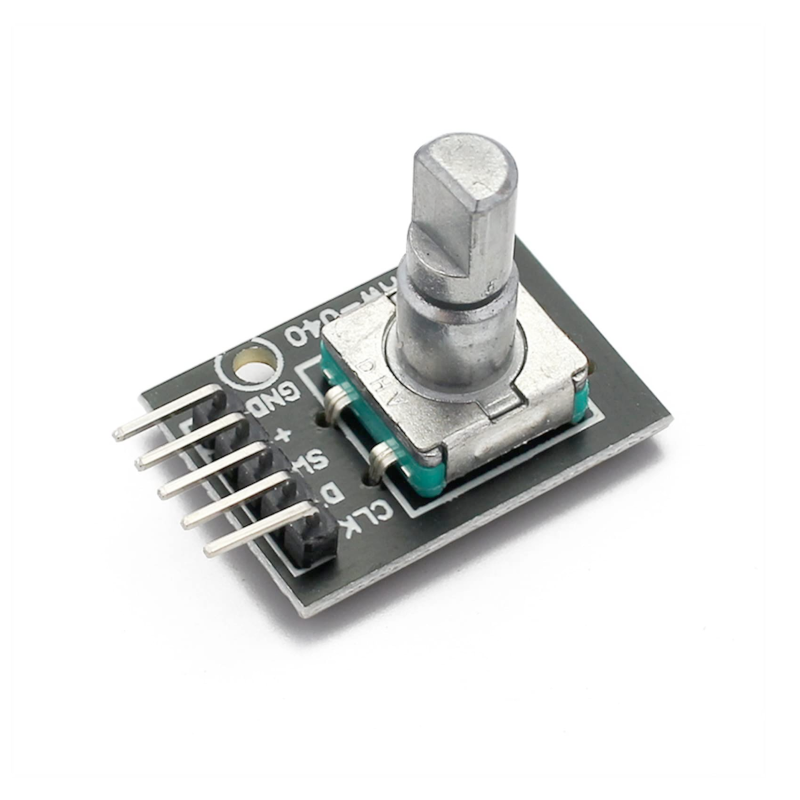

KY-040 Rotary Encoder Module

View on Amazon

Overview

About KY-040 Rotary Encoder Module

The KY-040 Rotary Encoder Module is a rotary input device that provides information about the amount and direction of rotation. Unlike potentiometers, which have limited rotation angles, the KY-040 can rotate continuously, making it ideal for applications requiring precise control, such as volume adjustments, menu navigation, and motor speed control. The module also features a built-in push-button switch, adding an extra layer of functionality.

Get Your KY-040

Prices are subject to change. We earn from qualifying purchases as an Amazon Associate.

KY-040 Specifications

Complete technical specification details for KY-040 Rotary Encoder Module

📊 Technical Parameters

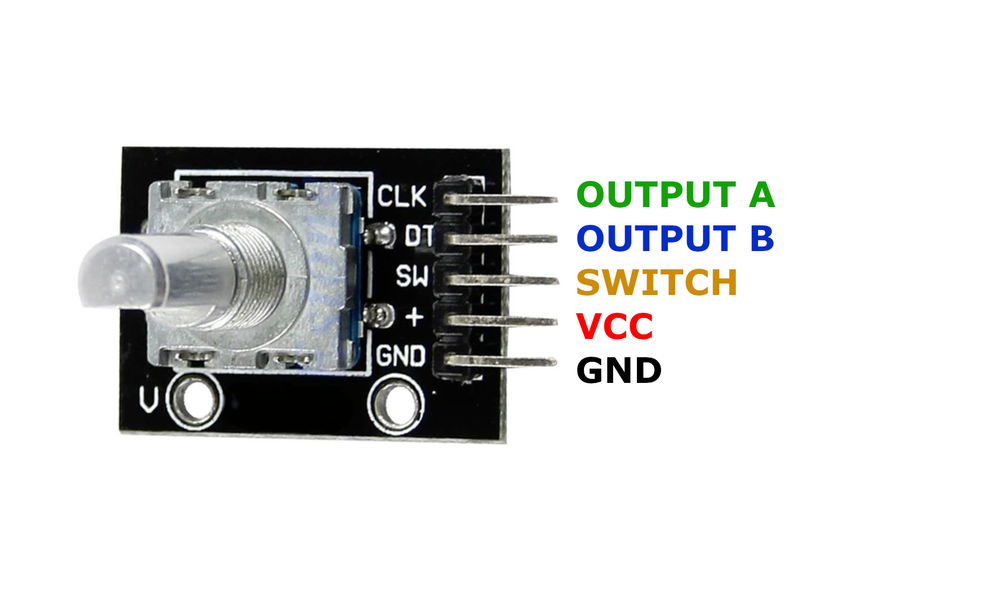

KY-040 Pinout

The **KY-040** is a 5-pin rotary encoder module with integrated push button:

Visual Pinout Diagram

Pin Types

Quick Tips

**Interface**: Digital quadrature encoder (2-phase),🔄 **Rotation**: Continuous 360° rotation (no limits)

**Direction**: CLK and DT phase relationship determines rotation direction,🔘 **Button**: Built-in push-button switch (active low)

**Power**: 3.3V or 5V operation,💡 **Debouncing**: Software debouncing recommended for stable readings

Pin Descriptions

| Pin Name | Type | Description | Notes |

|---|---|---|---|

1 CLK | Communication | Clock signal output | Pulses on rotation |

2 DT | Communication | Data signal output | Phase-shifted pulses for direction detection |

3 SW | Control | Switch/button signal | Active low when pressed |

4 VCC | Power | Power supply | 3.3V or 5V |

5 GND | Power | Ground connection |

Wiring KY-040 to ESP32

To interface the **KY-040** with an **ESP32** for rotary input:

Pin Connections

| KY-040 Pin | Connection | ESP32 Pin | Description |

|---|---|---|---|

1 VCC Required | 3.3V | Power supply | |

2 GND Required | GND | Ground | |

3 CLK Required | GPIO18 | Clock input (any GPIO) | |

4 DT Required | GPIO19 | Data input (any GPIO) | |

5 SW Optional | GPIO21 | Button input (any GPIO) |

**Interrupt Pins**: Use interrupt-capable GPIO pins for best response

**GPIO Selection**: Any digital GPIO pins work, shown pins are examples

**Voltage**: Use 3.3V to avoid level shifting

**Software**: Implement debouncing and state machine for direction detection

**Button Optional**: SW pin not required if button functionality not needed

KY-040 Troubleshooting

Common issues and solutions to help you get your sensor working

Common Issues

Issue: The module does not respond or behaves erratically when the knob is rotated.

Solutions:

- Ensure all connections are secure and correctly wired according to the pinout diagram.

- Verify that the microcontroller's input pins are properly configured as inputs in the code.

- Check for proper power supply voltage (3.3V or 5V) to the module.

- Implement software debouncing to account for mechanical switch noise.

Issue: The detected rotation direction is opposite to the actual rotation.

Solutions:

- Swap the connections of the

CLKandDTpins to correct the direction detection. - Ensure that the code logic correctly interprets the sequence of pulses from the

CLKandDTpins.

Debugging Tips

Use the Serial Monitor to check for error messages and verify the sensor's output. Add debug prints in your code to track the sensor's state.

Use a multimeter to verify voltage levels and check for continuity in your connections. Ensure the power supply is stable and within the sensor's requirements.

Additional Resources

KY-040 Programming Examples

Ready-to-use code examples for different platforms and frameworks

#define CLK_PIN 3

#define DT_PIN 4

#define SW_PIN 5

int counter = 0;

int currentStateCLK;

int lastStateCLK;

bool currentStateSW;

bool lastStateSW;

void setup() {

pinMode(CLK_PIN, INPUT);

pinMode(DT_PIN, INPUT);

pinMode(SW_PIN, INPUT_PULLUP);

lastStateCLK = digitalRead(CLK_PIN);

lastStateSW = digitalRead(SW_PIN);

Serial.begin(9600);

Serial.println("KY-040 Rotary Encoder Test");

}

void loop() {

currentStateCLK = digitalRead(CLK_PIN);

if (currentStateCLK != lastStateCLK) {

if (digitalRead(DT_PIN) != currentStateCLK) {

counter++;

} else {

counter--;

}

Serial.print("Position: ");

Serial.println(counter);

}

lastStateCLK = currentStateCLK;

currentStateSW = digitalRead(SW_PIN);

if (currentStateSW == LOW && lastStateSW == HIGH) {

Serial.println("Button Pressed");

}

lastStateSW = currentStateSW;

delay(50);

}This Arduino code sets up the KY-040 rotary encoder using three pins: CLK (Clock), DT (Data), and SW (Switch). It initializes these pins as inputs and continuously monitors the rotation direction and button presses.

When the encoder knob is turned, the CLK and DT pins generate pulses. By comparing the sequence of these pulses, the code determines whether the encoder is rotating clockwise or counterclockwise:

- If the

DTsignal is opposite to theCLKsignal, the counter increments (clockwise rotation). - If the

DTsignal matches theCLKsignal, the counter decrements (counterclockwise rotation).

The position counter is updated accordingly and printed to the serial monitor.

The built-in push-button switch (SW) is also monitored. If pressed, a message is printed to the serial monitor.

A delay(50) is used to debounce the encoder readings, ensuring stable detection of rotation and button presses.

#include <stdio.h>

#include "freertos/FreeRTOS.h"

#include "freertos/task.h"

#include "driver/gpio.h"

#define CLK_PIN GPIO_NUM_18

#define DT_PIN GPIO_NUM_19

#define SW_PIN GPIO_NUM_21

volatile int counter = 0;

volatile int lastStateCLK;

void IRAM_ATTR encoder_isr_handler(void* arg) {

int currentStateCLK = gpio_get_level(CLK_PIN);

if (currentStateCLK != lastStateCLK) {

if (gpio_get_level(DT_PIN) != currentStateCLK) {

counter++;

} else {

counter--;

}

printf("Position: %d\n", counter);

}

lastStateCLK = currentStateCLK;

}

void app_main(void) {

gpio_config_t io_conf = {

.intr_type = GPIO_INTR_ANYEDGE,

.mode = GPIO_MODE_INPUT,

.pin_bit_mask = (1ULL << CLK_PIN) | (1ULL << DT_PIN) | (1ULL << SW_PIN),

.pull_up_en = GPIO_PULLUP_ENABLE

};

gpio_config(&io_conf);

lastStateCLK = gpio_get_level(CLK_PIN);

gpio_install_isr_service(0);

gpio_isr_handler_add(CLK_PIN, encoder_isr_handler, NULL);

printf("KY-040 Rotary Encoder Test\n");

while (1) {

if (gpio_get_level(SW_PIN) == 0) {

printf("Button Pressed\n");

}

vTaskDelay(pdMS_TO_TICKS(100));

}

}This ESP-IDF code configures the KY-040 rotary encoder on GPIO18 (CLK), GPIO19 (DT), and GPIO21 (SW). It uses an interrupt service routine (ISR) to detect changes in the encoder's rotation and update a counter. Additionally, it checks for button presses in the main loop and prints the status to the console.

sensor:

- platform: rotary_encoder

pin_a: GPIO18

pin_b: GPIO19

name: "KY-040 Rotary Encoder"

min_value: -1000

max_value: 1000

resolution: 1

binary_sensor:

- platform: gpio

pin:

number: GPIO21

mode: INPUT_PULLUP

name: "KY-040 Button"This ESPHome configuration sets up the KY-040 rotary encoder with GPIO18 and GPIO19 for rotation detection and GPIO21 for the push button. The encoder is configured with a minimum and maximum value range, and its resolution is set to 1 step per increment.

platformio.ini

[env:esp32]

platform = espressif32

board = esp32dev

framework = arduinomain.cpp

#include <Arduino.h>

#define CLK_PIN 18

#define DT_PIN 19

#define SW_PIN 21

volatile int counter = 0;

int lastStateCLK;

void IRAM_ATTR rotary_encoder() {

int currentStateCLK = digitalRead(CLK_PIN);

if (currentStateCLK != lastStateCLK) {

if (digitalRead(DT_PIN) != currentStateCLK) {

counter++;

} else {

counter--;

}

Serial.print("Position: ");

Serial.println(counter);

}

lastStateCLK = currentStateCLK;

}

void setup() {

pinMode(CLK_PIN, INPUT);

pinMode(DT_PIN, INPUT);

pinMode(SW_PIN, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(CLK_PIN), rotary_encoder, CHANGE);

Serial.begin(115200);

Serial.println("KY-040 Rotary Encoder Test");

}

void loop() {

if (digitalRead(SW_PIN) == LOW) {

Serial.println("Button Pressed");

delay(100);

}

}This PlatformIO code configures GPIO18 (CLK), GPIO19 (DT), and GPIO21 (SW) for the KY-040 rotary encoder. It uses an interrupt to detect changes in rotation and updates a counter accordingly. The push button state is also monitored and printed to the serial monitor when pressed.

import machine

import time

CLK_PIN = machine.Pin(18, machine.Pin.IN, machine.Pin.PULL_UP)

DT_PIN = machine.Pin(19, machine.Pin.IN, machine.Pin.PULL_UP)

SW_PIN = machine.Pin(21, machine.Pin.IN, machine.Pin.PULL_UP)

counter = 0

last_state_clk = CLK_PIN.value()

while True:

current_state_clk = CLK_PIN.value()

if current_state_clk != last_state_clk:

if DT_PIN.value() != current_state_clk:

counter += 1

else:

counter -= 1

print("Position:", counter)

last_state_clk = current_state_clk

if SW_PIN.value() == 0:

print("Button Pressed")

time.sleep(0.1)

time.sleep(0.05)This MicroPython script configures GPIO18 (CLK), GPIO19 (DT), and GPIO21 (SW) for the KY-040 rotary encoder. It continuously monitors the encoder rotation and updates a counter while also detecting button presses.

Wrapping Up KY-040

The ESP32 KY-040 Rotary Encoder Module is a powerful KY-0xx module sensor that offers excellent performance and reliability. With support for multiple development platforms including Arduino, ESP-IDF, ESPHome, PlatformIO, and MicroPython, it's a versatile choice for your IoT projects.

Best Practices

For optimal performance, ensure proper wiring and follow the recommended configuration for your chosen development platform.

Safety First

Always verify power supply requirements and pin connections before powering up your project to avoid potential damage.

Ready to Start Building?

Now that you have all the information you need, it's time to integrate the KY-040 into your ESP32 project and bring your ideas to life!

Explore Alternative Sensors

Looking for alternatives to the KY-040? Check out these similar sensors that might fit your project needs.

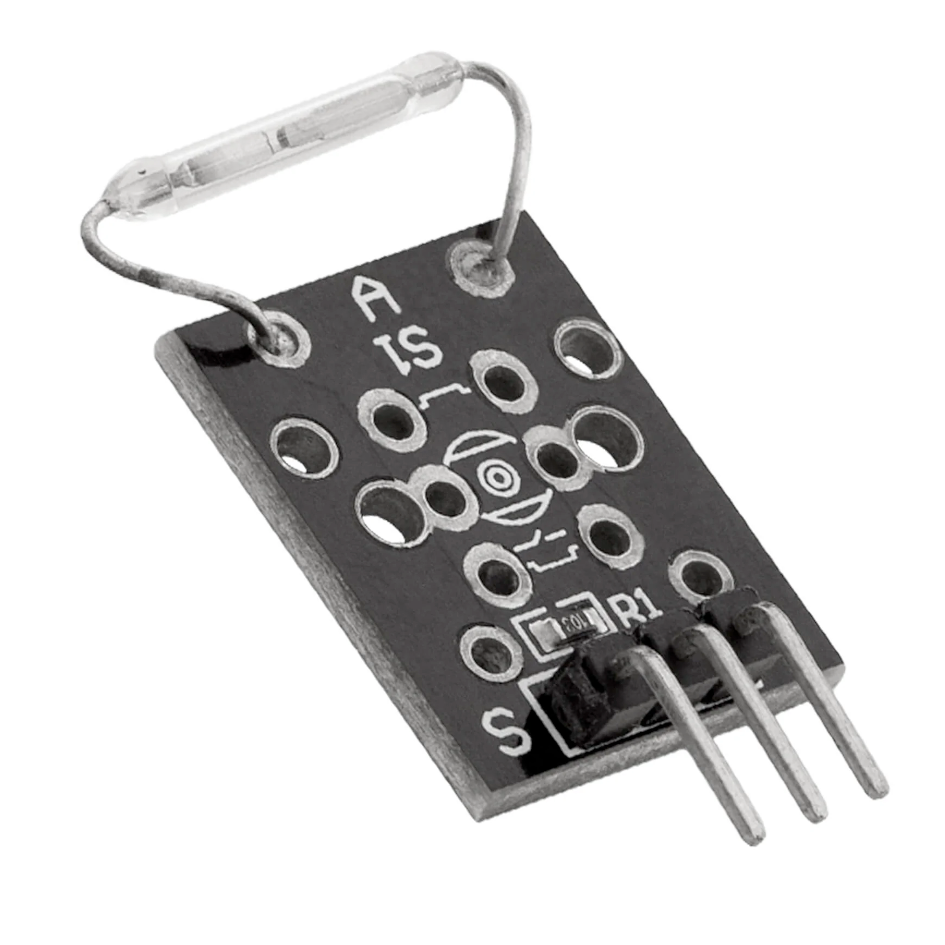

The KY-021 is a mini magnetic reed switch module that detects the presence of a magnetic field. It provides a digital signal output, making...

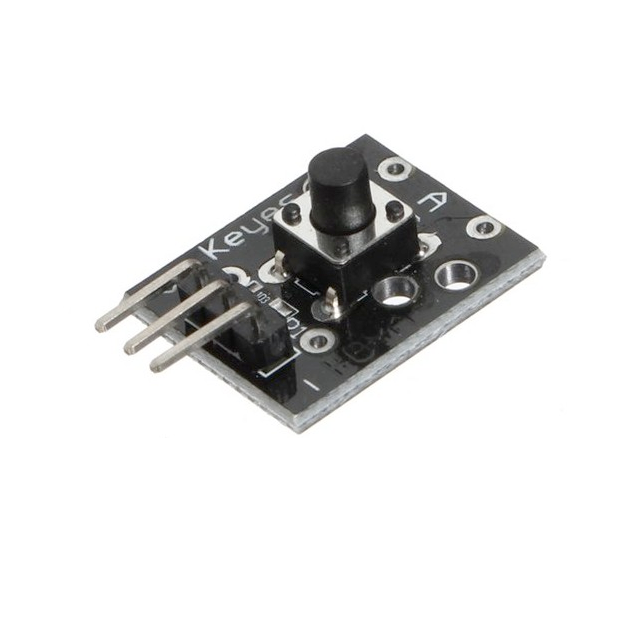

The KY-004 is a key switch module equipped with a tactile push-button. It provides a digital output signal when pressed, making it ideal for...