SHT35 Temperature and Humidity Sensor

View on Amazon

Overview

About SHT35 Temperature and Humidity Sensor

The SHT35, developed by Sensirion, is the premium model in the SHT3x series, offering superior accuracy and reliability. It is designed for demanding applications such as industrial monitoring, HVAC systems, and environmental data logging.

⚡ Key Features

- Highest Accuracy in the SHT3x Series – Superior precision for critical applications.

- I²C Communication – Easy integration with ESP32, Arduino, and other microcontrollers.

- Long-Term Stability – Ensures consistent and reliable environmental measurements.

- Ideal for Professional Use – Used in scientific monitoring, industrial automation, and smart HVAC systems.

🔗 Looking for cost-effective alternatives? Consider:

Get Your SHT35

Prices are subject to change. We earn from qualifying purchases as an Amazon Associate.

SHT35 Specifications

Complete technical specification details for SHT35 Temperature and Humidity Sensor

📊 Technical Parameters

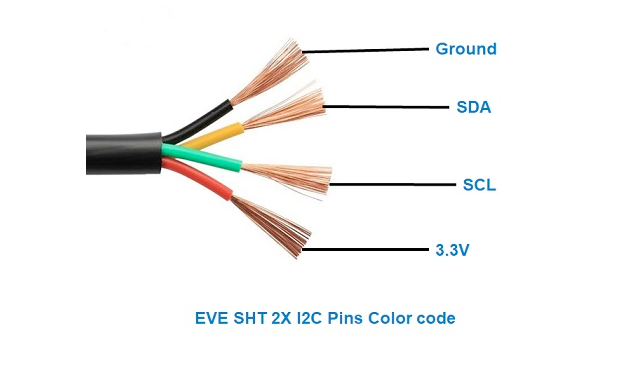

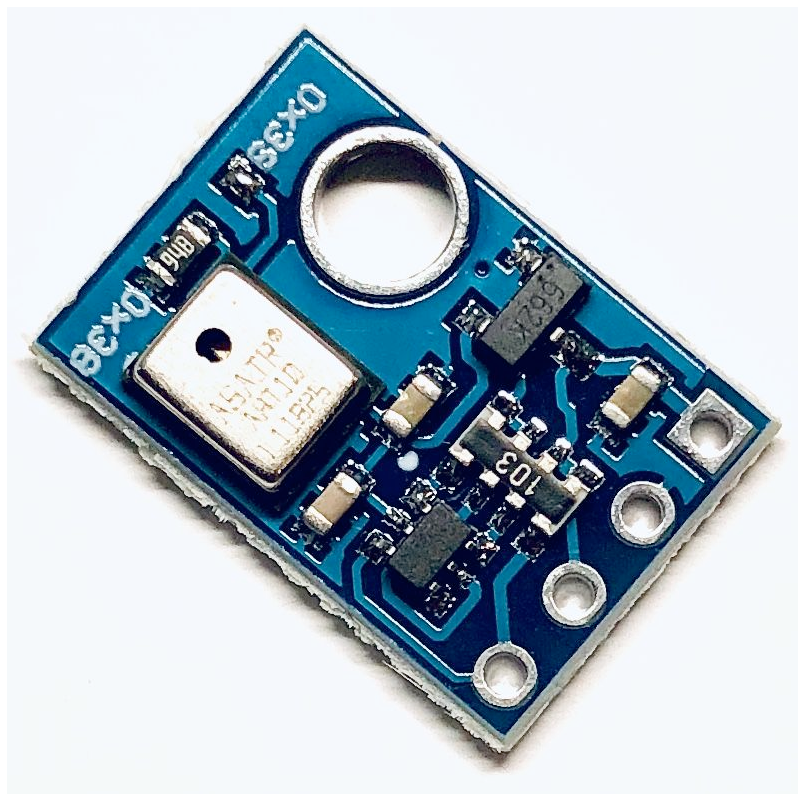

SHT35 Pinout

The SHT35 uses standard I²C communication with 4 pins, offering top-tier accuracy and durability.

Visual Pinout Diagram

Pin Types

Quick Tips

Standard I²C interface for easy integration,📡 Default I²C address is 0x44 or 0x45 (configurable)

Top accuracy: ±0.1°C temp, ±1.5% humidity,⚡ Wide voltage range (2.4V-5.5V) for industrial use

Premium sensor for demanding professional applications

Pin Descriptions

| Pin Name | Type | Description | Notes |

|---|---|---|---|

1 VDD | Power | Power supply input (2.4V to 5.5V) | Wide voltage range for industrial applications |

2 GND | Power | Ground connection | Connect to ESP32 ground |

3 SDA | Communication | I²C data line | Bidirectional data communication |

4 SCL | Communication | I²C clock line | Clock signal from master device |

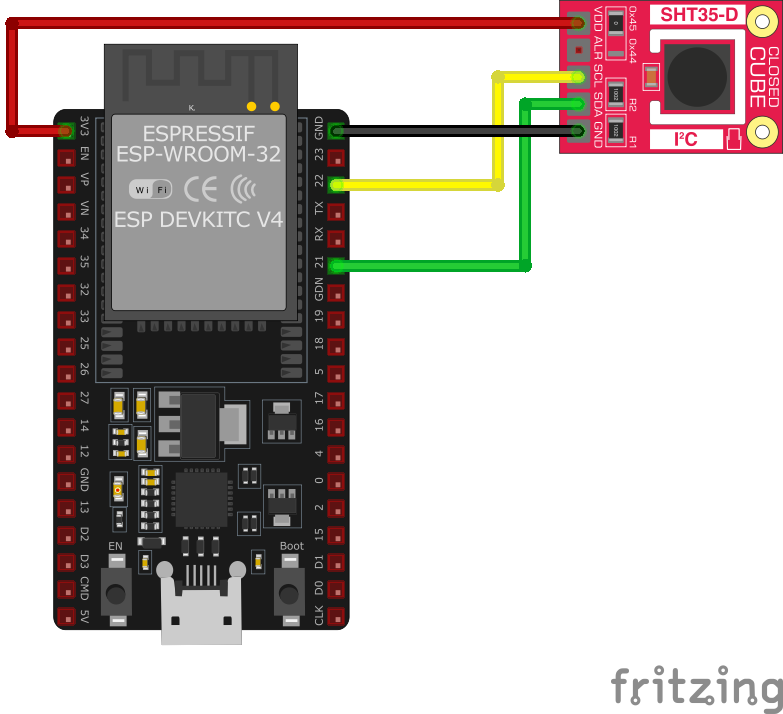

Wiring SHT35 to ESP32

Connect the SHT35 using standard I²C interface for maximum precision measurements.

Visual Wiring Diagram

Connection Status

Protocol

Pin Connections

| SHT35 Pin | Connection | ESP32 Pin | Description |

|---|---|---|---|

1 VDD Required | 3.3V | Power supply (2.4V to 5.5V supported) | |

2 GND Required | GND | Ground connection | |

3 SDA Required | GPIO21 | I²C data line (default SDA) | |

4 SCL Required | GPIO22 | I²C clock line (default SCL) |

GPIO21/22 are default I²C pins on ESP32

I²C address is 0x44 or 0x45 (check your module)

Add 10kΩ pull-up resistors on SDA/SCL if needed

Can share I²C bus with other devices

SHT35 Troubleshooting

Common issues and solutions to help you get your sensor working

Common Issues

Issue: When compiling code for the SHT35 sensor using the Seeed Studio library, the following error occurs: 'yield' was not declared in this scope.

Possible causes include outdated or incorrect library versions that are incompatible with the current Arduino IDE.

Solution: Update the Arduino IDE to the latest version and ensure that the Seeed Studio SHT35 library is also up to date. If the issue persists, manually edit the library files to include the appropriate declarations or consider using an alternative library compatible with the SHT35 sensor. ([forum.arduino.cc](https://forum.arduino.cc/t/sht35-library-error/1110371))

Issue: When running a Python script on a Raspberry Pi to read data from the SHT35 sensor, the following error is encountered after a period of successful readings: Errno 121 Remote I/O Error.

Possible causes include intermittent I2C communication issues, loose connections, or power supply instability.

Solution: Check all physical connections between the Raspberry Pi and the SHT35 sensor to ensure they are secure. Verify that the I2C bus is properly configured and that pull-up resistors are correctly implemented. Additionally, monitor the power supply to ensure it remains stable during operation. ([forum.seeedstudio.com](https://forum.seeedstudio.com/t/errno-121-on-sht35/7113/1))

Issue: The SHT35 sensor is not detected on the I2C bus, resulting in failed communication attempts.

Possible causes include incorrect wiring, improper I2C address configuration, or sensor malfunction.

Solution: Verify that the SDA and SCL lines are correctly connected to the appropriate pins on the microcontroller. Ensure that the sensor's I2C address matches the address specified in the code (default is 0x44). If using multiple I2C devices, confirm that there are no address conflicts. Test the sensor with an I2C scanner to detect its presence on the bus. ([arduinolearning.com](https://www.arduinolearning.com/code/sht35-humidity-sensor-and-arduino-example.php))

Issue: When accessing the SHT35 sensor data from multiple clients simultaneously, the sensor becomes unresponsive, requiring a system reboot to restore functionality.

Possible causes include concurrent access to the I2C bus leading to communication conflicts.

Solution: Implement a data caching mechanism where a single process reads data from the sensor at regular intervals and stores it. Clients can then access the cached data instead of querying the sensor directly. This approach prevents simultaneous I2C access and reduces the risk of communication issues. ([forums.raspberrypi.com](https://forums.raspberrypi.com/viewtopic.php?t=261745))

Debugging Tips

Use the Serial Monitor to check for error messages and verify the sensor's output. Add debug prints in your code to track the sensor's state.

Use a multimeter to verify voltage levels and check for continuity in your connections. Ensure the power supply is stable and within the sensor's requirements.

Additional Resources

SHT35 Programming Examples

Ready-to-use code examples for different platforms and frameworks

#include <Wire.h>

#include "Adafruit_SHT31.h"

Adafruit_SHT31 sht31 = Adafruit_SHT31();

void setup() {

Serial.begin(115200);

while (!Serial) delay(10);

if (!sht31.begin(0x44)) { // Set to 0x45 for alternate I2C address

Serial.println("Couldn't find SHT35");

while (1) delay(1);

}

}

void loop() {

float t = sht31.readTemperature();

float h = sht31.readHumidity();

if (!isnan(t) && !isnan(h)) { // check if 'is not a number'

Serial.print("Temp *C = "); Serial.print(t); Serial.print(" ");

Serial.print("Hum. % = "); Serial.println(h);

} else {

Serial.println("Failed to read from SHT35 sensor");

}

delay(1000);

}#include <stdio.h>

#include "freertos/FreeRTOS.h"

#include "freertos/task.h"

#include "driver/i2c.h"

#define I2C_MASTER_SCL_IO 22 /*!< GPIO number used for I2C master clock */

#define I2C_MASTER_SDA_IO 21 /*!< GPIO number used for I2C master data */

#define I2C_MASTER_NUM I2C_NUM_0 /*!< I2C master I2C port number */

#define I2C_MASTER_FREQ_HZ 100000 /*!< I2C master clock frequency */

#define SHT35_SENSOR_ADDR 0x44 /*!< SHT35 I2C address */

static esp_err_t i2c_master_init(void) {

i2c_config_t conf = {

.mode = I2C_MODE_MASTER,

.sda_io_num = I2C_MASTER_SDA_IO,

.scl_io_num = I2C_MASTER_SCL_IO,

.sda_pullup_en = GPIO_PULLUP_ENABLE,

.scl_pullup_en = GPIO_PULLUP_ENABLE,

.master.clk_speed = I2C_MASTER_FREQ_HZ,

};

esp_err_t err = i2c_param_config(I2C_MASTER_NUM, &conf);

if (err != ESP_OK) {

return err;

}

return i2c_driver_install(I2C_MASTER_NUM, conf.mode, 0, 0, 0);

}

void read_sht35_sensor() {

uint8_t data[6];

i2c_master_write_read_device(I2C_MASTER_NUM, SHT35_SENSOR_ADDR, NULL, 0, data, sizeof(data), pdMS_TO_TICKS(1000));

uint16_t temp_raw = (data[0] << 8) | data[1];

uint16_t hum_raw = (data[3] << 8) | data[4];

float temperature = -45 + 175 * ((float)temp_raw / 65535.0);

float humidity = 100 * ((float)hum_raw / 65535.0);

printf("Temperature: %.2f °C, Humidity: %.2f %%\n", temperature, humidity);

}

void app_main() {

ESP_ERROR_CHECK(i2c_master_init());

while (1) {

read_sht35_sensor();

vTaskDelay(pdMS_TO_TICKS(2000));

}

}sensor:

- platform: sht3x

address: 0x44

temperature:

name: "Living Room Temperature"

humidity:

name: "Living Room Humidity"

update_interval: 60splatformio.ini

[env:esp32dev]

platform = espressif32

board = esp32dev

framework = arduino

lib_deps =

adafruit/Adafruit SHT31 Library @ ^1.2.0

monitor_speed = 115200main.cpp

#include <Wire.h>

#include "Adafruit_SHT31.h"

Adafruit_SHT31 sht35 = Adafruit_SHT31();

void setup() {

Serial.begin(115200);

while (!Serial) delay(10);

if (!sht35.begin(0x44)) { // Default I2C address for SHT35

Serial.println("Couldn't find SHT35 sensor!");

while (1) delay(1);

}

}

void loop() {

float temperature = sht35.readTemperature();

float humidity = sht35.readHumidity();

if (!isnan(temperature) && !isnan(humidity)) { // Check if readings are valid

Serial.print("Temperature: ");

Serial.print(temperature);

Serial.println(" °C");

Serial.print("Humidity: ");

Serial.print(humidity);

Serial.println(" %");

} else {

Serial.println("Failed to read from SHT35 sensor!");

}

delay(2000); // Wait 2 seconds between readings

}from machine import I2C, Pin

import time

# SHT35 default I2C address

SHT35_I2C_ADDRESS = 0x44

# Initialize I2C communication (SDA=21, SCL=22)

i2c = I2C(0, scl=Pin(22), sda=Pin(21))

def read_sht35():

# Send measurement command (high repeatability, no clock stretching)

i2c.writeto(SHT35_I2C_ADDRESS, b'\x24\x00')

time.sleep(0.015) # Wait for measurement to complete

# Read 6 bytes of data

data = i2c.readfrom(SHT35_I2C_ADDRESS, 6)

# Convert the data

temp_raw = (data[0] << 8) | data[1]

humidity_raw = (data[3] << 8) | data[4]

# Calculate temperature and humidity

temperature = -45 + (175 * temp_raw / 65535.0)

humidity = 100 * humidity_raw / 65535.0

return temperature, humidity

while True:

try:

temperature, humidity = read_sht35()

print("Temperature: {:.2f} °C".format(temperature))

print("Humidity: {:.2f} %".format(humidity))

except Exception as e:

print("Failed to read from SHT35 sensor:", e)

time.sleep(2)Wrapping Up SHT35

The ESP32 SHT35 Temperature and Humidity Sensor is a powerful environment sensor that offers excellent performance and reliability. With support for multiple development platforms including Arduino, ESP-IDF, ESPHome, PlatformIO, and MicroPython, it's a versatile choice for your IoT projects.

Best Practices

For optimal performance, ensure proper wiring and follow the recommended configuration for your chosen development platform.

Safety First

Always verify power supply requirements and pin connections before powering up your project to avoid potential damage.

Ready to Start Building?

Now that you have all the information you need, it's time to integrate the SHT35 into your ESP32 project and bring your ideas to life!

Explore Alternative Sensors

Looking for alternatives to the SHT35? Check out these similar sensors that might fit your project needs.

AHT10 Temperature and Humidity Sensor

The AHT10 is an advanced, fully calibrated, and highly integrated temperature and humidity sensor that provides reliable, precise...

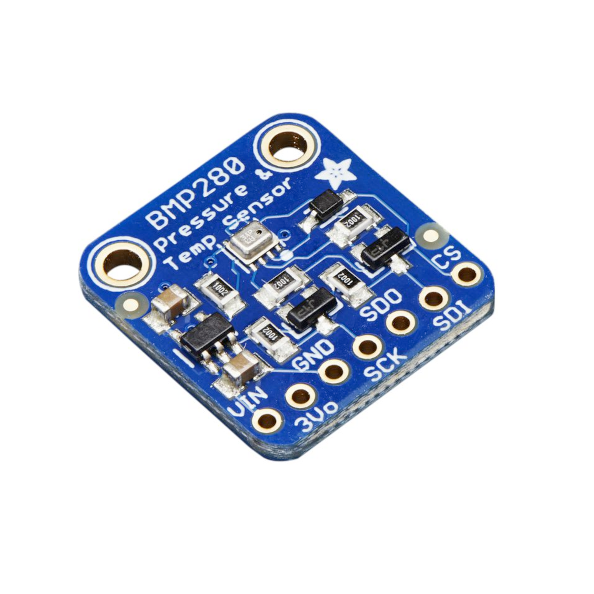

BMP280 Barometric Pressure and Temperature Sensor

The BMP280 is a high-precision digital barometric pressure and temperature sensor, ideal for weather monitoring, altimetry, and navigation....

DHT21 / AM2301A Temperature and Humidity Sensor

The DHT21 is a reliable sensor for measuring temperature and humidity, offering calibrated digital output and ease of integration with...