MG996R Servo

View on Amazon

Overview

About MG996R Servo

The MG996R is a high-torque metal gear servo motor designed for robotics, RC models, and heavy-duty DIY projects. With strong metal gears and a powerful torque output, it is ideal for applications requiring strength and durability, such as robotic arms and steering systems.

⚡ Key Features

- Operating Voltage: 4.8V – 7.2V

- Torque: Up to 11 kg·cm at 6V

- Angular Range: ~120° (60° in each direction)

- PWM Control: 1ms (0°), 1.5ms (midpoint), 2ms (max position)

- Weight: ~55g

- Size: 40.7mm × 19.7mm × 42.9mm

- Metal Gears: Increased durability and load capacity

Looking for the best ESP32-compatible servo motors? Check out our ESP32 Servo Motor Guide. 🚀

Get Your mg996r

💡 Prices are subject to change. We earn from qualifying purchases as an Amazon Associate.

mg996r Specifications

Complete technical specification details for MG996R Servo

📊 Technical Parameters

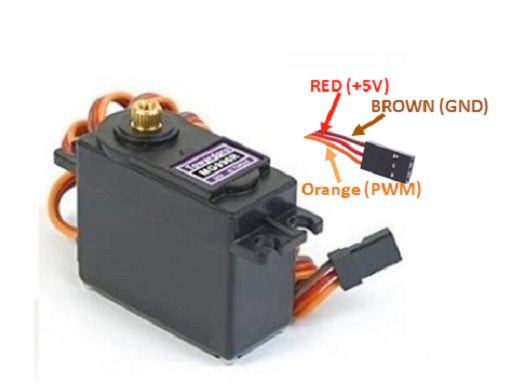

mg996r Pinout

The MG996R is a high-torque 3-wire servo motor with GND (brown), +5V (red), and DATA (orange) wires.

Visual Pinout Diagram

Pin Types

Quick Tips

Object],[object Object]

Object],[object Object]

gears for heavy-duty applications

Pin Descriptions

| Pin Name | Type | Description | Notes |

|---|---|---|---|

1 GND | Power | Ground connection. Connect to ESP32 GND and external power supply ground. | Essential for both power and signal reference. |

2 +5V | Power | Power supply input (4.8V-7.2V). Requires external power supply capable of 2.5A peak. | DO NOT power from ESP32 5V pin - insufficient current capacity. |

3 DATA | PWM | PWM control signal. Pulse width: 1ms (0°), 1.5ms (midpoint), 2ms (max). | Connect to a PWM-capable GPIO pin (e.g., GPIO 18). |

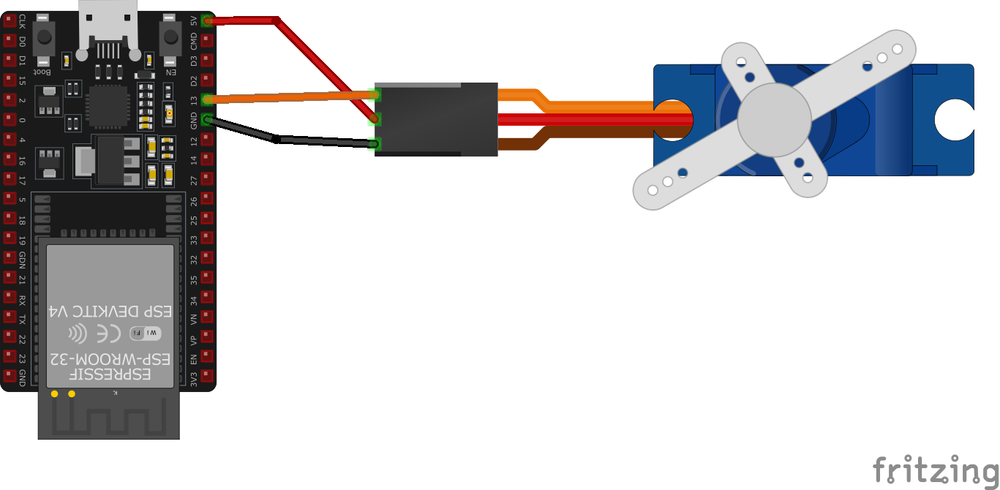

Wiring mg996r to ESP32

To control the MG996R servo with an ESP32, connect the brown wire to GND, red wire to an external 5-7.2V power supply (NOT ESP32), and orange wire to a PWM GPIO pin.

Visual Wiring Diagram

Connection Status

Protocol

Pin Connections

| mg996r Pin | Connection | ESP32 Pin | Description |

|---|---|---|---|

1 GND (brown) Required | GND + External Supply GND | Common ground for ESP32 and external power supply. | |

2 +5V (red) Required | External 5-7.2V Supply | Dedicated power supply (2.5A+ capacity). DO NOT use ESP32 5V pin. | |

3 DATA (orange) Required | GPIO 18 | PWM control signal (50Hz, 1-2ms pulse width). |

Object]

Object]

Object]

Object]

470µF-1000µF capacitor across power supply to reduce voltage spikes

all grounds together (ESP32 + power supply + servo)

mg996r Troubleshooting

Common issues and solutions to help you get your sensor working

Common Issues

Issue: The MG996R servo does not move as expected or exhibits erratic behavior.

Possible causes include insufficient power supply, incorrect wiring, or incompatible control signals.

Solution: Ensure the servo is powered by an adequate external power source, as it can draw up to 2.5A at stall. Verify that the control signal is connected to a PWM-capable pin on the microcontroller, and that the signal parameters match the servo's specifications.

Issue: The MG996R servo becomes excessively hot during operation.

Possible causes include overloading the servo, continuous operation under high torque, or inadequate power supply.

Solution: Avoid stalling the servo for extended periods, as this can lead to overheating. Ensure that the load applied to the servo is within its torque specifications. Use a stable and adequately rated power supply to prevent voltage drops that could cause the servo to overheat.

Issue: The MG996R servo exhibits jittery or twitchy movements during operation.

Possible causes include electrical noise, insufficient power supply, or signal interference.

Solution: Ensure a stable and adequate power supply to the servo, as voltage fluctuations can cause erratic behavior. Implement proper grounding and consider adding decoupling capacitors to filter out electrical noise. Check for any sources of signal interference and ensure that control signals are clean and within the appropriate voltage levels.

Issue: The MG996R servo does not return to its neutral position accurately.

Possible causes include calibration issues, mechanical wear, or internal potentiometer faults.

Solution: Perform a calibration by sending a neutral position command (typically 1500µs pulse width) and adjust as necessary. Inspect the servo for signs of mechanical wear or damage. If the problem persists, the internal potentiometer may be faulty, and replacing the servo could be necessary.

Debugging Tips

Use the Serial Monitor to check for error messages and verify the sensor's output. Add debug prints in your code to track the sensor's state.

Use a multimeter to verify voltage levels and check for continuity in your connections. Ensure the power supply is stable and within the sensor's requirements.

Additional Resources

mg996r Programming Examples

Ready-to-use code examples for different platforms and frameworks

Wrapping Up mg996r

The ESP32 MG996R Servo is a powerful servo sensor that offers excellent performance and reliability. With support for multiple development platforms including Arduino, ESP-IDF, ESPHome, PlatformIO, and MicroPython, it's a versatile choice for your IoT projects.

Best Practices

For optimal performance, ensure proper wiring and follow the recommended configuration for your chosen development platform.

Safety First

Always verify power supply requirements and pin connections before powering up your project to avoid potential damage.

Ready to Start Building?

Now that you have all the information you need, it's time to integrate the mg996r into your ESP32 project and bring your ideas to life!

Explore Alternative Sensors

Looking for alternatives to the mg996r? Check out these similar sensors that might fit your project needs.

MG90S Mini Servo

The MG90S is a robust micro servo motor designed for robotics and DIY projects. Operating on 4.8V to 6V, it provides up to 2.2 kg·cm torque,...

General Servo

<p>PWM servos are controlled using Pulse Width Modulation signals to adjust their position or speed. They are widely used in robotics, RC...

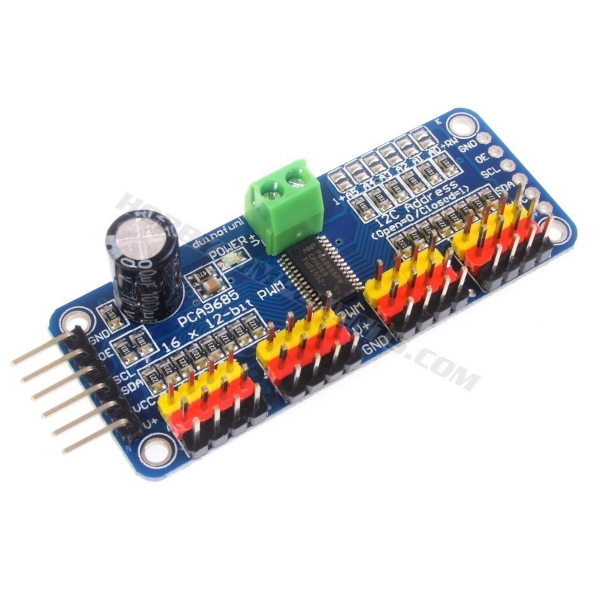

PCA9685 16-Channel 12-bit PWM/Servo Driver

The PCA9685 is a 16-channel, 12-bit PWM controller from NXP, widely used to control servos, LEDs, and other PWM devices. It communicates...