ESP32 RC522 RFID/NFC Module

Overview

The RC522 RFID/NFC module offers an affordable and reliable solution for integrating NFC and RFID functionality into your projects. Its compact size, multi-protocol support, and robust performance make it a great choice for a wide range of applications.

About RC522 RFID/NFC Module

The RC522 is a cost-effective and compact RFID/NFC module designed for proximity identification and security applications. It supports multiple communication protocols (SPI, I²C, UART), making it easy to integrate with ESP32, Arduino, and other microcontrollers.

⚡ Key Features

- Multi-Protocol Support – Communicates via SPI, I²C, and UART.

- ISO/IEC 14443 Type A Compatibility – Works with RFID/NFC cards and tags.

- Versatile Applications – Ideal for access control, payment systems, and secure authentication.

- Compact & Low Power – Suitable for embedded security projects.

With its flexibility and affordability, the RC522 is a great choice for NFC-based applications requiring secure and contactless authentication. 🚀

Where to Buy

Prices are subject to change. We earn from qualifying purchases as an Amazon Associate.

Technical Specifications

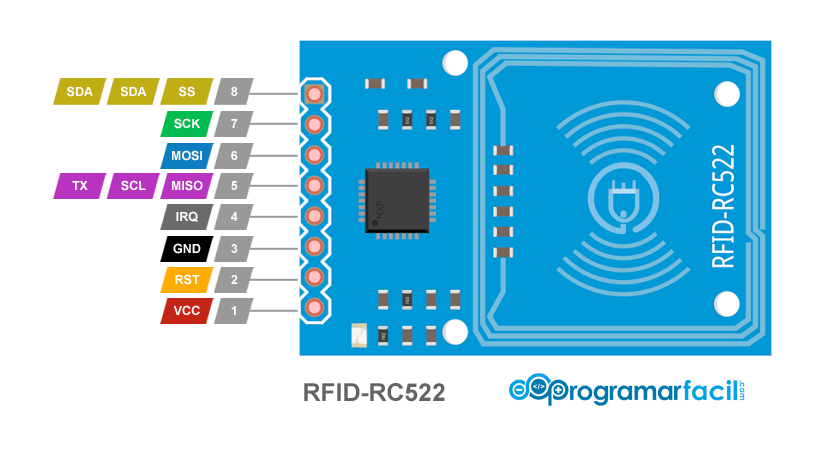

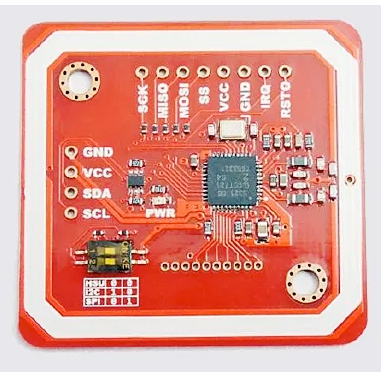

Pinout Configuration

The VCC pin is used to supply power to the sensor, and it typically requires 3.3V or 5V (refer to the datasheet for specific voltage requirements). The GND pin is the ground connection and must be connected to the ground of your ESP32.

The RC522 pinout includes:

- VCC: Power supply input (3.3V).

- GND: Ground connection.

- RST: Reset signal input (active low).

- IRQ: Interrupt signal output.

- MISO: SPI Master In Slave Out.

- MOSI: SPI Master Out Slave In.

- SCK: SPI clock line.

- SDA: I2C data line or SPI slave select.

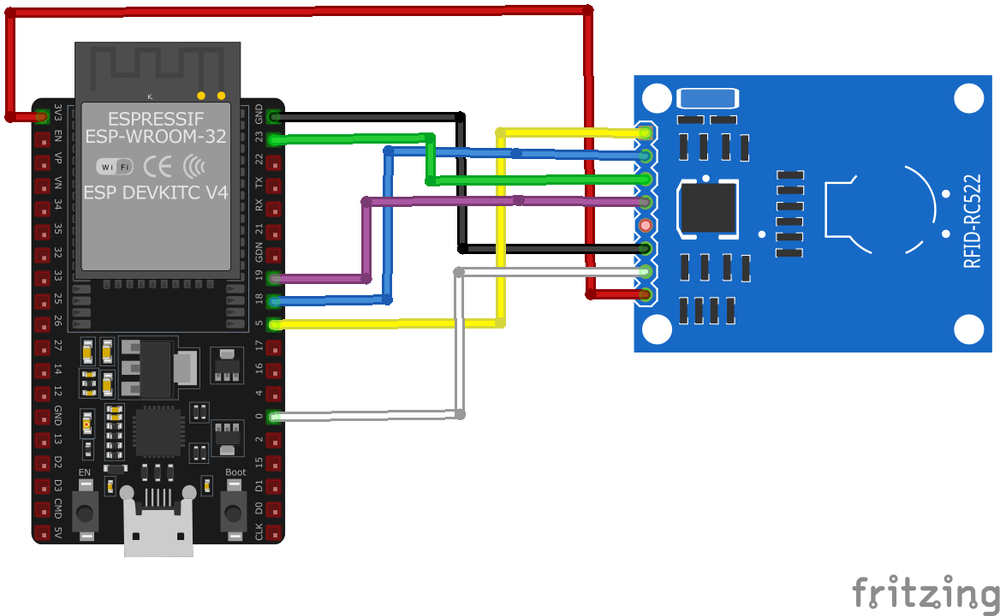

Wiring with ESP32

- Connect

VCCto a stable 3.3V power supply. - Connect

GNDto the system ground. - For SPI: Connect

MISO,MOSI,SCK, andSDAto the respective SPI pins on the microcontroller. UseRSTfor reset control. - For I2C: Connect

SDAto the microcontroller's SDA pin andSCKto the SCL pin. - For UART: Use appropriate UART lines (if available on the module version).

Troubleshooting Guide

Common Issues

❌ Module Fails to Power On

Issue: The RC522 module does not power up or respond to commands.

Possible causes include insufficient power supply, incorrect wiring, or faulty hardware.

Solution: Ensure the module is connected to a stable power source within the recommended voltage range of 3.3V to 5V. Verify that all connections are secure and correctly configured. If the problem persists, consider testing the module with a different power source or replacing it.

🔌 Communication Interface Not Working

Issue: The module fails to communicate with the microcontroller over the chosen interface (SPI).

Possible causes include incorrect wiring, improper interface selection, or incompatible voltage levels.

Solution: Double-check the wiring to ensure correct connections for SPI communication. For SPI, verify the MOSI, MISO, SCK, and SS lines are properly connected. Ensure that the microcontroller's SPI interface is enabled and configured correctly.

🚫 Unable to Read Tags

Issue: The module initializes correctly but fails to read RFID tags.

Possible causes include incorrect antenna orientation, insufficient power supply, or interference from nearby electronic devices.

Solution: Ensure the module's antenna is properly oriented and positioned near the tags. Verify that the power supply provides adequate current for the module's operation. Keep the module away from sources of electromagnetic interference.

⚠️ Inconsistent Tag Detection

Issue: The module detects tags intermittently or with delays.

Possible causes include low-quality tags, environmental interference, or firmware issues.

Solution: Test with different tags to rule out tag quality issues. Ensure the operating environment is free from strong electromagnetic interference. Update the module's firmware to the latest version to benefit from bug fixes and improvements.

💻 Library or Software Issues

Issue: The module operates erratically or produces errors during operation.

Possible causes include outdated or incompatible libraries, incorrect initialization, or software bugs.

Solution: Ensure that the latest version of the MFRC522 library is installed and compatible with your development environment. Review the initialization code to confirm that the module is set up correctly. Consult the module's documentation and community forums for guidance on proper usage.

Debugging Tips

🔍 Serial Monitor

Use the Serial Monitor to check for error messages and verify the sensor's output. Add debug prints in your code to track the sensor's state.

⚡ Voltage Checks

Use a multimeter to verify voltage levels and check for continuity in your connections. Ensure the power supply is stable and within the sensor's requirements.

Additional Resources

Code Examples

Arduino Example

#include <SPI.h>

#include <MFRC522.h>

#define RST_PIN 9

#define SS_PIN 10

MFRC522 rfid(SS_PIN, RST_PIN);

void setup() {

Serial.begin(115200);

SPI.begin();

rfid.PCD_Init();

Serial.println("RC522 initialized. Waiting for cards...");

}

void loop() {

if (!rfid.PICC_IsNewCardPresent() || !rfid.PICC_ReadCardSerial()) {

delay(50);

return;

}

Serial.print("Card UID: ");

for (byte i = 0; i < rfid.uid.size; i++) {

Serial.print(rfid.uid.uidByte[i], HEX);

Serial.print(" ");

}

Serial.println();

rfid.PICC_HaltA();

}setup function initializes the module, while the loop scans for RFID cards and prints their UIDs when detected. Additional functionality, such as reading or writing card data, can be implemented using the MFRC522 library.ESP-IDF Example

#include <stdio.h>

#include "driver/spi_master.h"

#include "driver/gpio.h"

#include "freertos/task.h"

#include "rc522.h"

#define RST_PIN GPIO_NUM_21

#define SS_PIN GPIO_NUM_22

#define MISO_PIN GPIO_NUM_19

#define MOSI_PIN GPIO_NUM_23

#define SCK_PIN GPIO_NUM_18

void app_main() {

printf("Initializing RC522...");

rc522_config_t config = {

.spi_miso_io = MISO_PIN,

.spi_mosi_io = MOSI_PIN,

.spi_sck_io = SCK_PIN,

.spi_cs_io = SS_PIN,

.reset_io = RST_PIN

};

rc522_handle_t handle = rc522_create(&config);

if (handle == NULL) {

printf("Failed to initialize RC522\n");

return;

}

while (true) {

rc522_tag_t tag;

if (rc522_read_tag(handle, &tag) == ESP_OK) {

printf("Tag UID: ");

for (int i = 0; i < tag.uid_size; i++) {

printf("%02X ", tag.uid[i]);

}

printf("\n");

}

vTaskDelay(pdMS_TO_TICKS(500));

}

}rc522_read_tag function retrieves tag information when available. Additional functionalities like writing to cards can be implemented using the RC522 driver.ESPHome Example

spi:

clk_pin: GPIO18

mosi_pin: GPIO23

miso_pin: GPIO19

rc522:

cs_pin: GPIO22

rst_pin: GPIO21

update_interval: 2s

sensor:

- platform: rc522

uid:

name: "RFID Tag UID"

log:

name: "RFID Log"PlatformIO Example

platformio.ini

[env:rc522]

platform = espressif32

board = esp32dev

framework = arduino

monitor_speed = 115200PlatformIO Example Code

#include <SPI.h>

#include <MFRC522.h>

#define RST_PIN 21

#define SS_PIN 22

MFRC522 rfid(SS_PIN, RST_PIN);

void setup() {

Serial.begin(115200);

SPI.begin();

rfid.PCD_Init();

Serial.println("RC522 initialized. Waiting for cards...");

}

void loop() {

if (!rfid.PICC_IsNewCardPresent() || !rfid.PICC_ReadCardSerial()) {

delay(50);

return;

}

Serial.print("Card UID: ");

for (byte i = 0; i < rfid.uid.size; i++) {

Serial.print(rfid.uid.uidByte[i], HEX);

Serial.print(" ");

}

Serial.println();

rfid.PICC_HaltA();

}MicroPython Example

from machine import Pin, SPI

from mfrc522 import MFRC522

import time

spi = SPI(1, baudrate=1000000, sck=Pin(18), mosi=Pin(23), miso=Pin(19))

rst = Pin(21, Pin.OUT)

cs = Pin(22, Pin.OUT)

reader = MFRC522(spi, cs, rst)

while True:

print("Waiting for card...")

(status, tag_type) = reader.request(reader.REQIDL)

if status == reader.OK:

(status, uid) = reader.anticoll()

if status == reader.OK:

print("Card UID:", [hex(i) for i in uid])

time.sleep(1)Conclusion

The ESP32 RC522 RFID/NFC Module is a powerful NFC sensor that offers excellent performance and reliability. With support for multiple development platforms including Arduino, ESP-IDF, ESPHome, PlatformIO, and MicroPython, it's a versatile choice for your IoT projects.

For optimal performance, ensure proper wiring and follow the recommended configuration for your chosen development platform.

Always verify power supply requirements and pin connections before powering up your project to avoid potential damage.